In January 2026, I.CEBERG participated in the TOKYO PROTOTYPE exhibition.

This series of articles introduces the works created by each MAISON.

For more details about the event, please visit here.

Overview of the Work

Beneath visible beauty lies the pulsation of life that continues to exist while connected to the environment and others, drifting through time.

This work uses tree roots that were once buried in the earth to express the core life force—the heat of life that lies at the foundation of life’s beauty.

The garment enveloping the roots symbolizes the warm soil that nurtures life, and the protected roots emit light reminiscent of the heartbeat of life.

That gentle light then quietly begins to illuminate its surroundings.

Credit

Maison : Takuma Sasaki

Costume Designer : Koshiro Ebata

Stylist : DAN (kelemmi)

Lighting Plan & Design : Satoshi Yanagisawa (Triple Bottom Line)

Lighting System & Mechanical Design : Yoshihiro Hirata (R2)

Technical Support : Giichi Endo (NICHINAN GROUP)

Photo by Yuya Shiokawa

Production Process

【Selecting and Processing Wood】

First, the base wood was prepared. This is a root from Sumatra that had been buried deep in the earth, never exposed to direct sunlight, and is extremely dense and durable.

The surface was covered with old bark, which was carefully removed and coated with lacquer. By applying just one coat, a natural rough texture is preserved, with a moderate sheen.

【3D Scanning】

The prepared wood was taken to Nichinan Co., Ltd. for 3D scanning. Using this data, the design of the clear branch was developed. Digitally reproducing the exact shape of the real wood made it possible to simultaneously advance the lighting design and costume production.

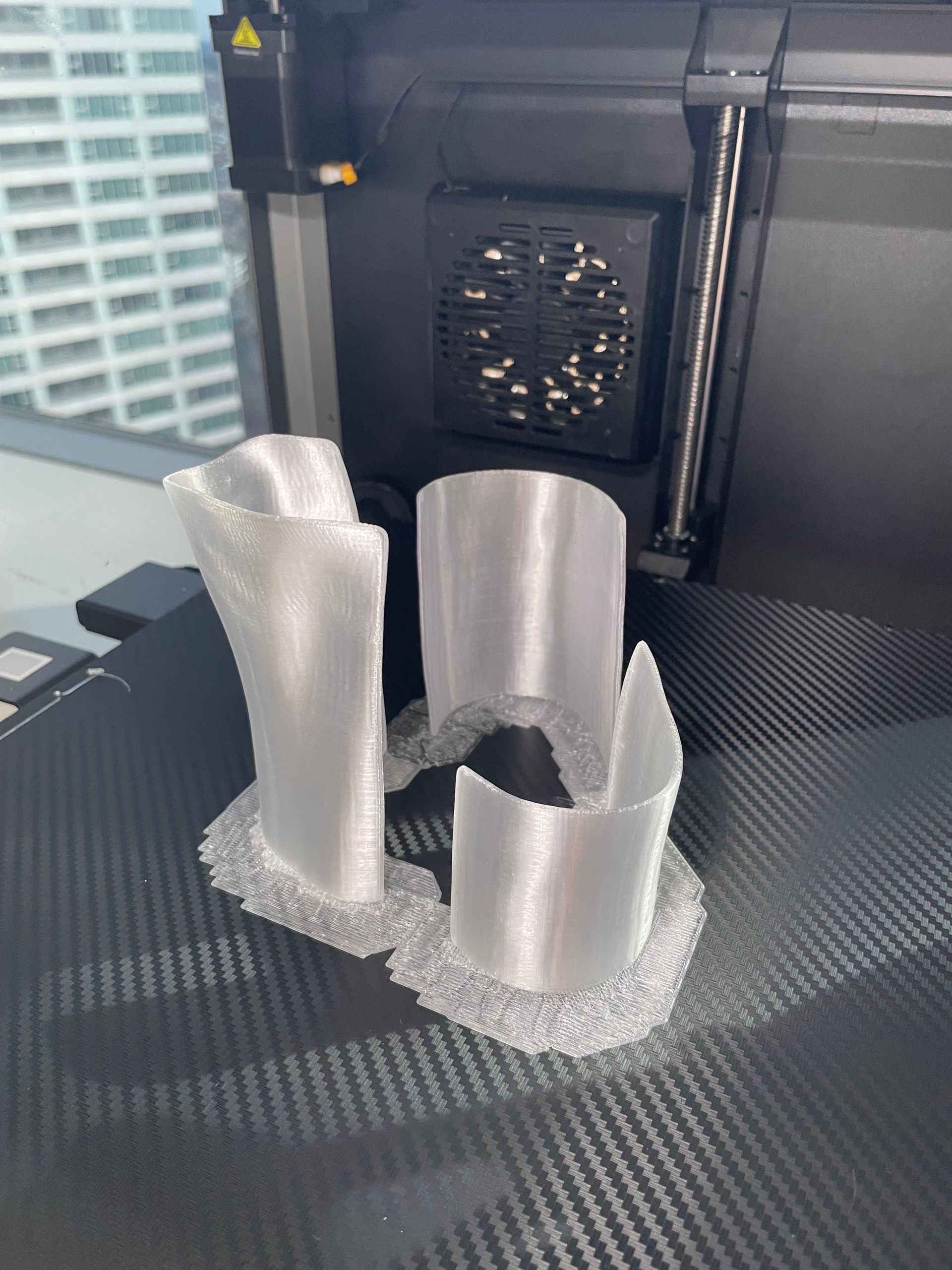

Using precise scan data, the form was output using a 3D printer.

Due to the size limitations of the 3D printer, the parts were printed in sections and then assembled.

A real piece of wood and a data-driven, fabricated counterpart

【Costume Design / R&D】

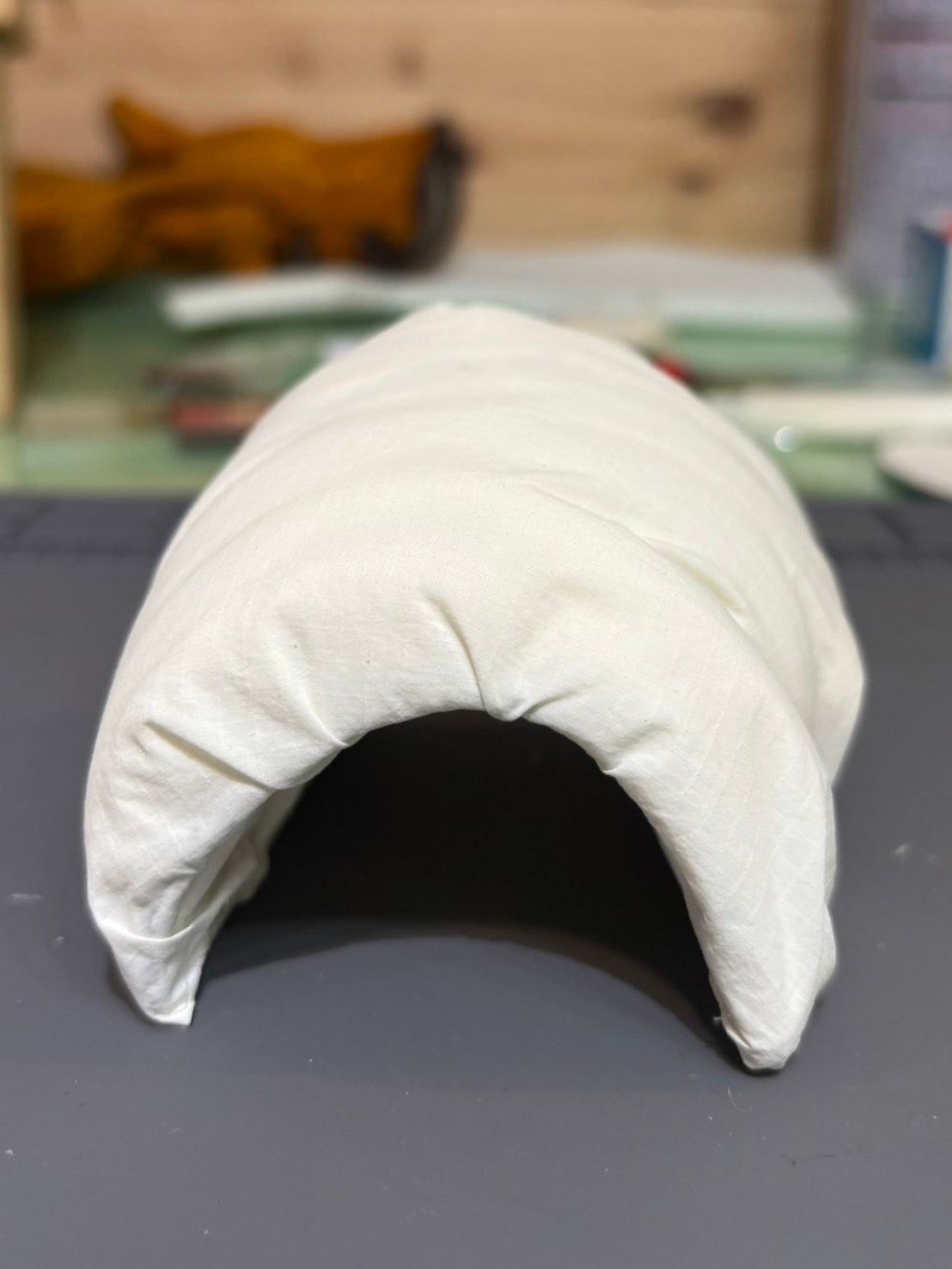

To explore directions for the costume design, R&D was conducted on how to express the volume of a down jacket. Decisions were made to divide the costume into parts and to use 3D printing to create skin-like components for each part.

【Costume Design】

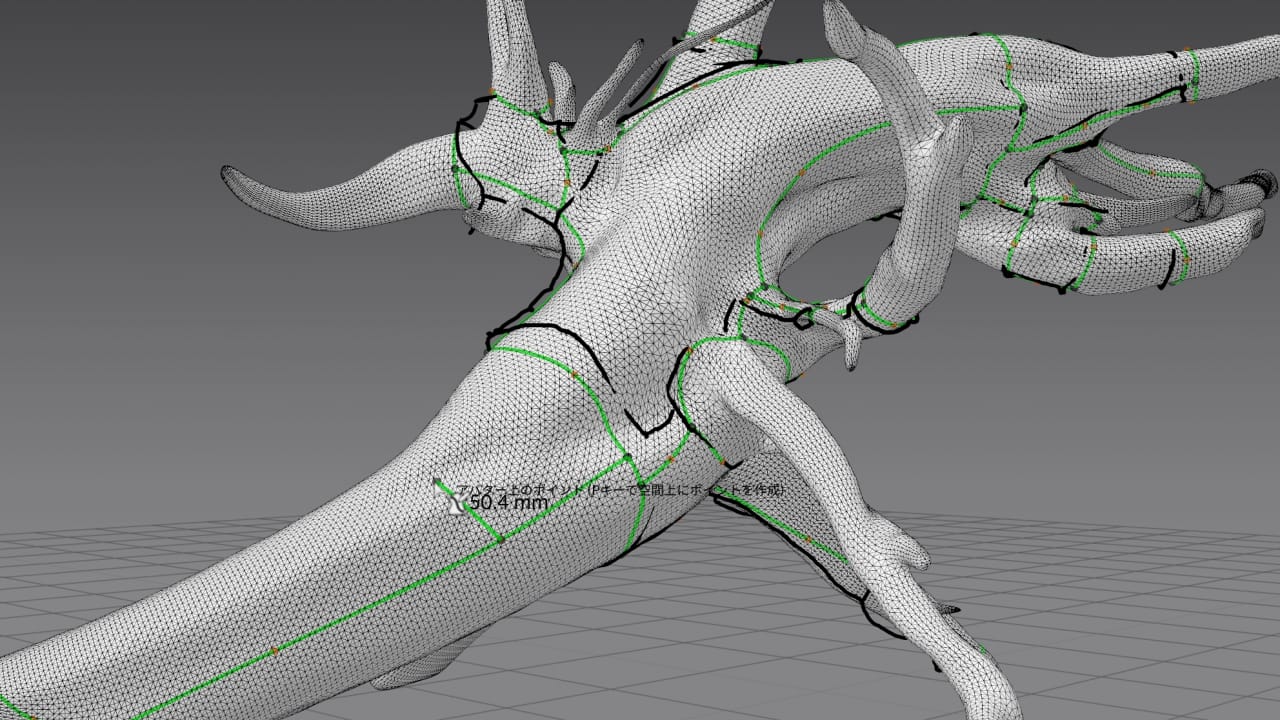

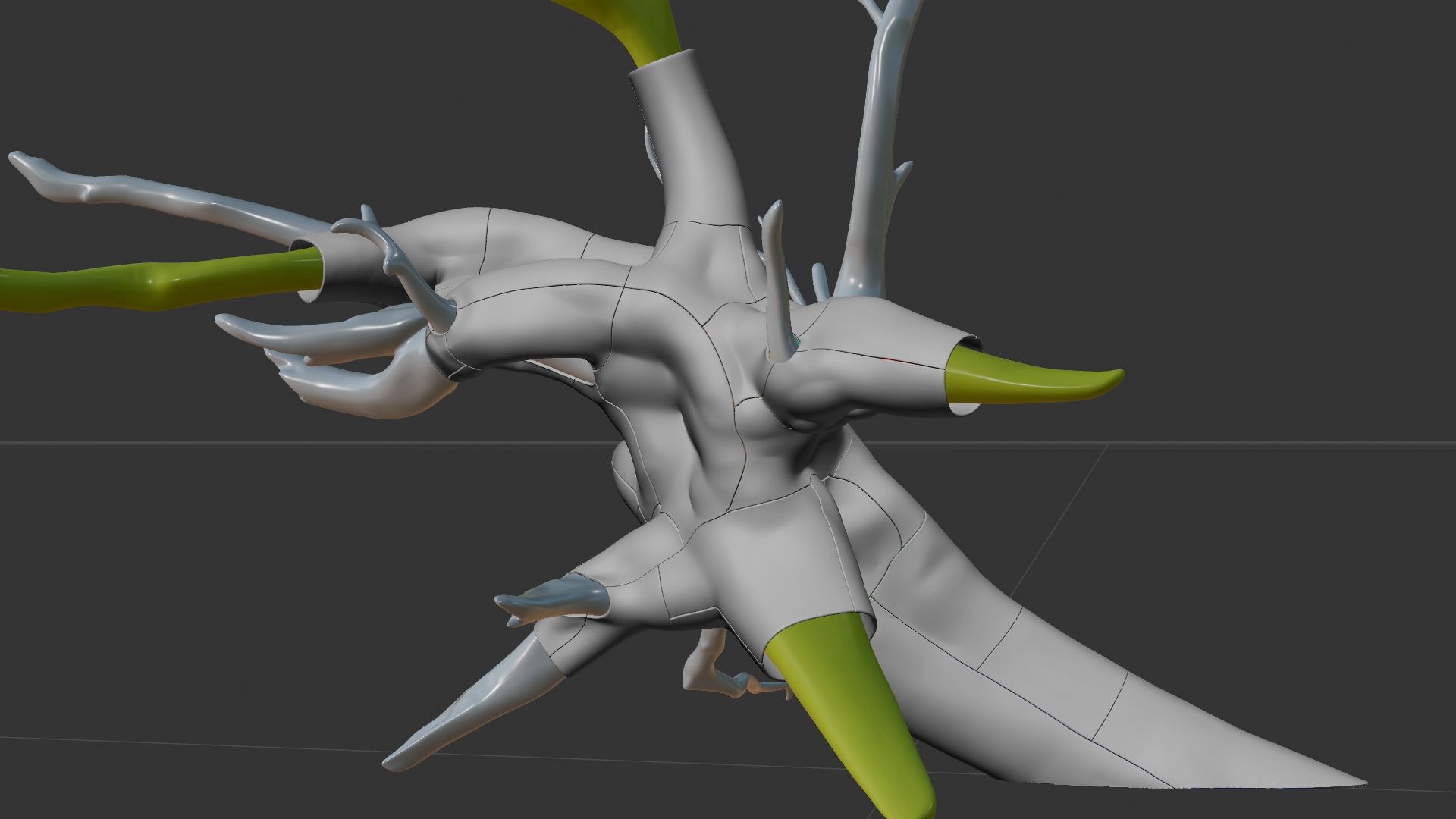

CG modeling was used to finalize the look of the costume before actual production.

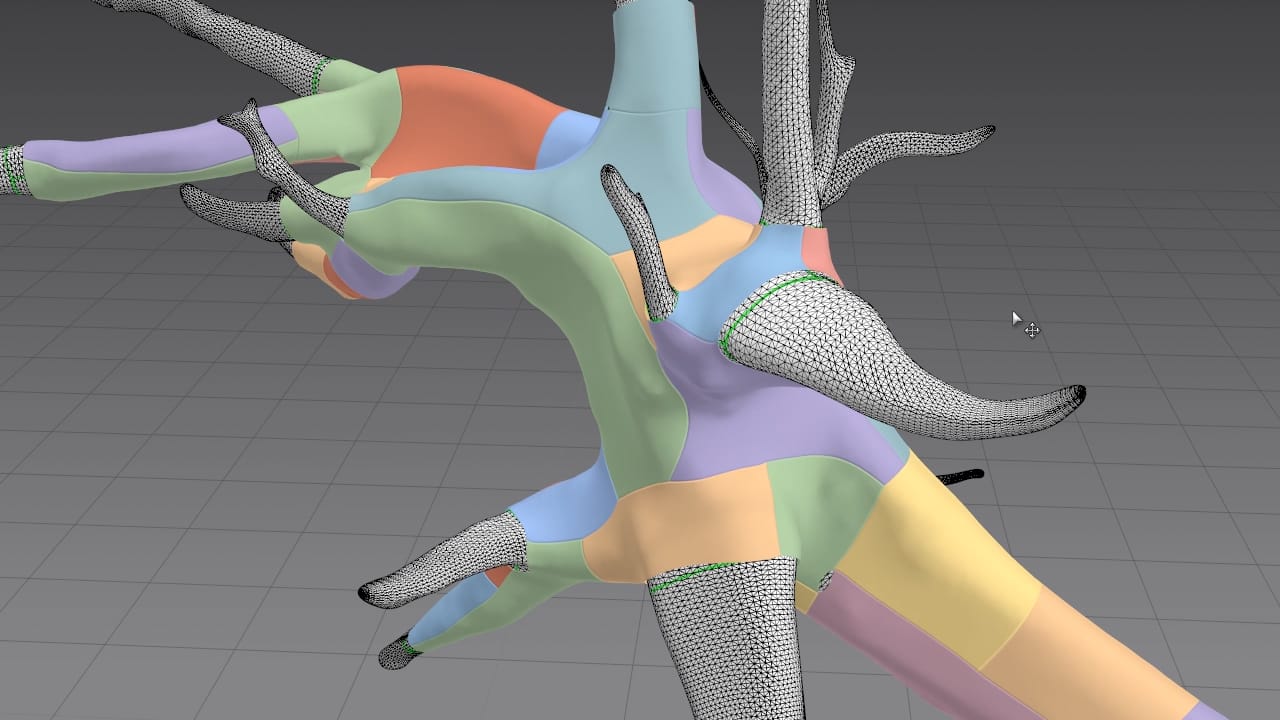

The boundaries of the skin parts were drawn directly onto the 3D model.

Faces were then created along the drawn boundaries.

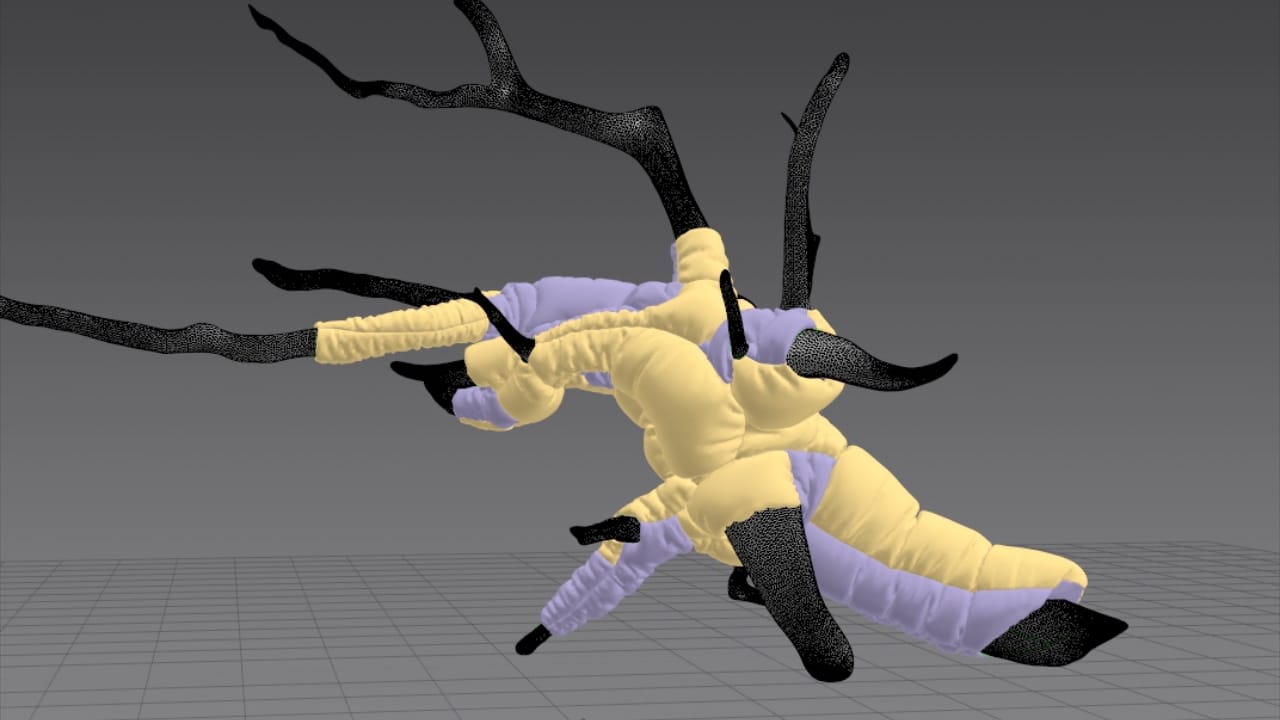

By adjusting parameters such as fabric softness and elasticity, a garment with a strong sense of volume was designed. This resulted in a visual reference that will serve as a guideline for future production.

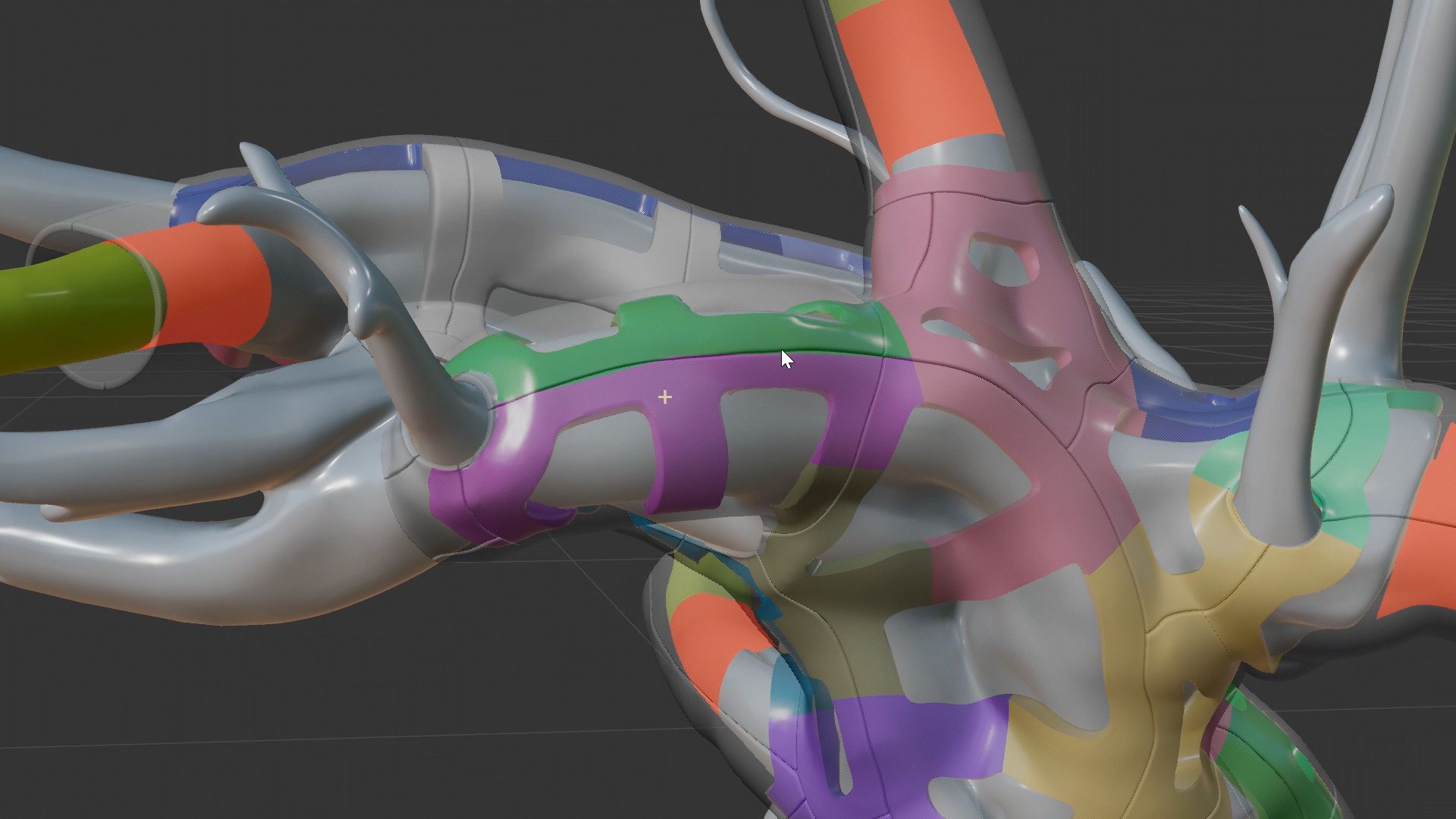

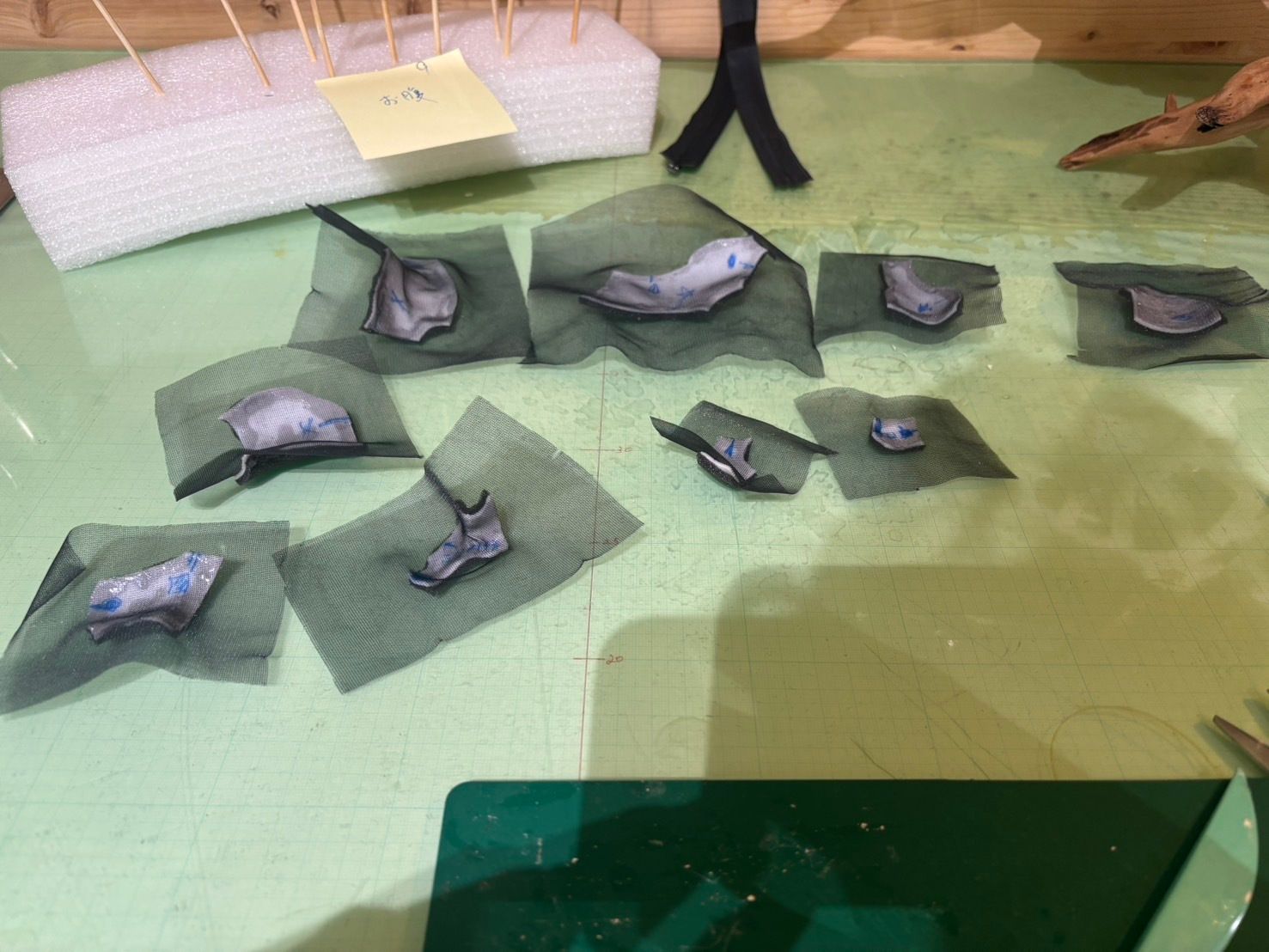

【Base Part Design for the Costume & Design of Heat Management Components】

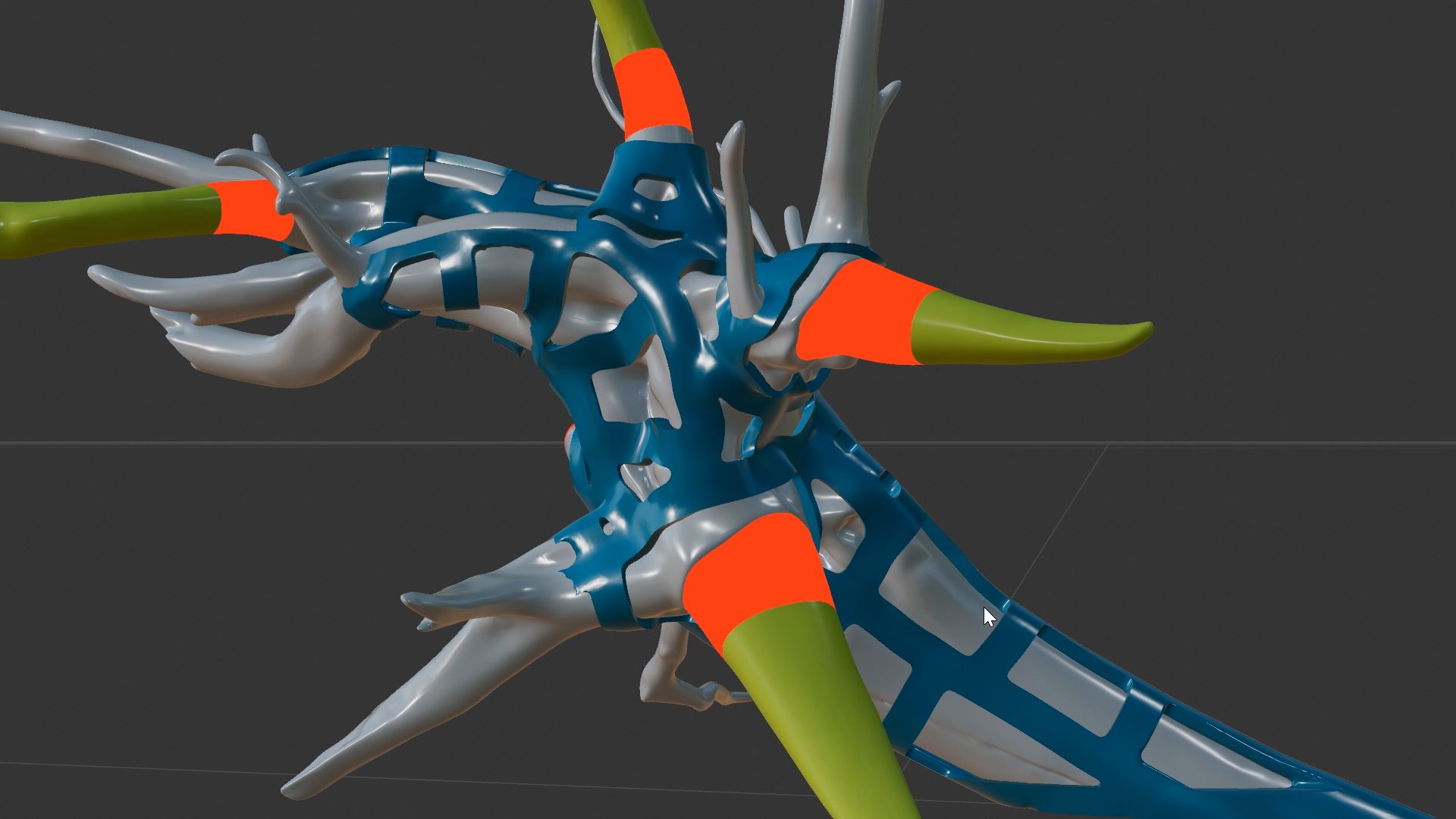

The base skin components and heat management parts were designed with attention to heat dissipation—placing LED lights so they do not touch the costume surface. Countless air bubbles were placed inside the clear branch to create a vein-like, muscular impression.

Simulation of clear branch placement and light-blocking tape application

Fabrication of 1.2 mm–thick skin parts

The skin parts and volume-building parts were designed to minimize tolerances as much as possible.

Design of 4.5 mm volume-building parts

The area surrounding the LEDs was designed to allow greater exposure to air as a heat management measure.

Air bubbles were injected into the clear branches using a material that is highly responsive to light.

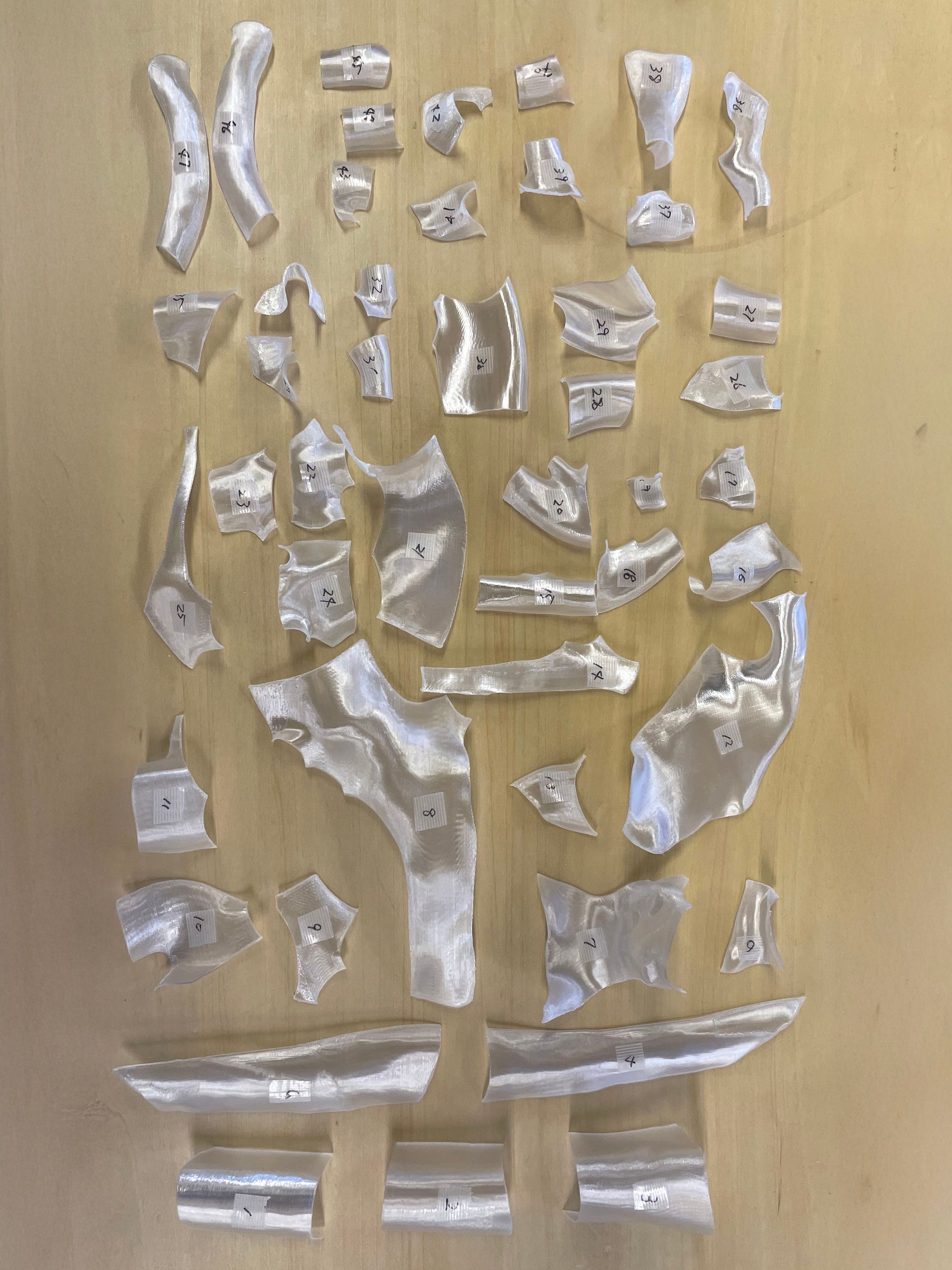

【3D Printing Output(Skin Parts & Volume-Building Parts)】

Because of size limitations in the 3D printer, the clear branches were printed in sections and assembled. The skin and heat management parts were produced using flame-resistant filament to ensure safety and functionality.

Output of the Skin Parts

The skin parts were divided into approximately 50 components.

Perfectly fitting volume-building parts

【3D Printing Output (Branches) & Wood Processing】

The scanned data was refined on a computer and then output using a 3D printer.

After printing with support structures, the parts were polished to achieve the desired finish.

Subsequently, the wood was processed to accommodate the lighting mechanism, and excess material at the contact points was carefully cut away.

(Nichinan)

【Installation of the Printed Clear Branches & LED Mechanism Assembly】

The clear branches produced at Nichinan were attached to the wood, and the lighting mechanism—including the LED components—was given a final inspection.

【Assembly of Skin Parts and Volume-Building Components / Lighting Mechanism Check & Wiring】

With all components except the costume prepared, the assembly process was carried out in a single, continuous phase.

【Final Costume Production】

Finally, costume production began in earnest. Emphasis was placed on the look of a down jacket, integrating zippers, buttons, and other small elements to fully realize the concept of wood wearing clothing.

The garment is designed to be removable; by unfastening the zipper,

it can be taken off just like a piece of clothing.

【Lighting Program Control】

The illumination of the five branches is individually controlled through programmed lighting sequences.

Taking visual guidance into consideration, the light intensity of each branch is adjusted one by one while observing the overall balance of the piece.

Both the timing and duration of illumination are controlled by the program. Each branch pulses gently and randomly, fading in and out at its own rhythm, until at certain moments all five branches begin to shine powerfully in unison.

This lighting behavior is designed to evoke the sensation of life breathing—an expression of pulsation and vital rhythm.